OEM manufacturer Open Floor Grating - I Shape Plain And Serrated Steel Grating – Chengsen

OEM manufacturer Open Floor Grating - I Shape Plain And Serrated Steel Grating – Chengsen Detail:

I Type Steel Plate Surface Treatment

Hot galvanizing, cold galvanizing, painting, dipping rust oil, no treatment (general stainless steel without treatment).

I Type Steel Plate Production Method

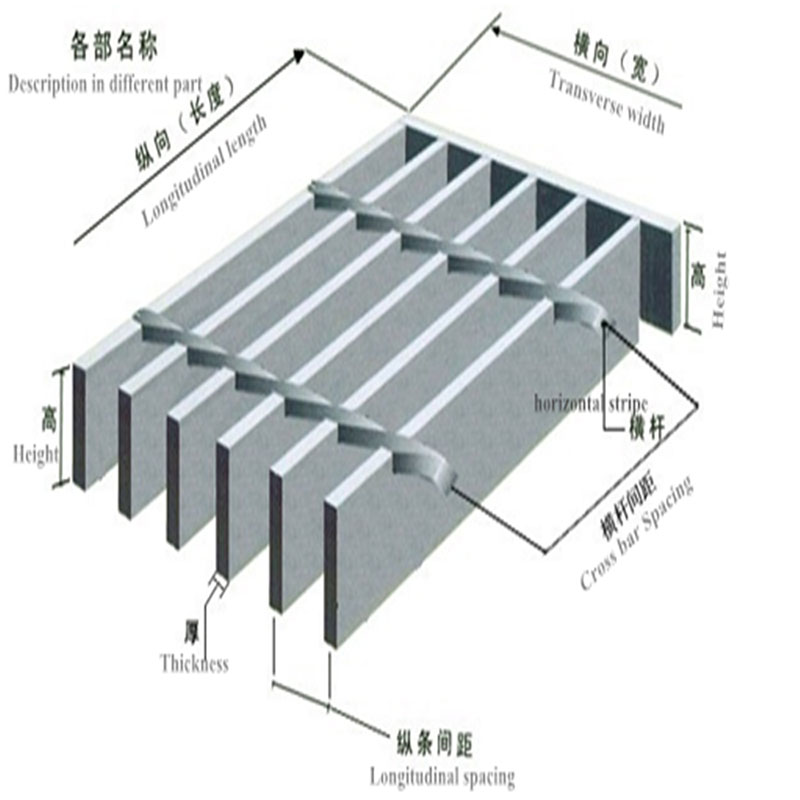

I type steel plate is composed of load flat steel and horizontal bar arranged according to a certain spacing of longitude and latitude, using 200 tons of hydraulic resistance welding automation equipment welding into the original plate, after cutting, opening, rimming and other processes processed into customer requirements.

Steel Grating I Type, Bearing Bars At 30mm Pitch

|

Type |

Beam |

Flange |

Abdominal |

Flange |

Theory |

Load |

ClearSpan |

||||||||||||||

|

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

|||||||

|

G757/30/50I |

75 |

7 |

4 |

12 |

126.1 |

U |

6460 |

1615 |

717 |

403 |

258 |

179 |

131 |

100 |

79 |

64 |

53 |

44 |

38 |

32 |

28 |

|

G757/30/100 I |

120.7 |

D |

0.09 |

0.37 |

0.83 |

1.47 |

2.3 |

3.31 |

4.5 |

5.88 |

7.47 |

9.25 |

11.26 |

13.3 |

15.89 |

18.11 |

20.99 |

||||

|

G657/30/50I |

65 |

7 |

4 |

10 |

110.1 |

U |

4862 |

1215 |

540 |

303 |

194 |

135 |

99 |

75 |

60 |

48 |

40 |

33 |

28 |

24 |

21 |

|

G657/30/100I |

104.8 |

D |

0.11 |

0.42 |

0.95 |

1.69 |

2.65 |

3.83 |

5.22 |

6.77 |

8.71 |

10.67 |

13.07 |

15.36 |

18.05 |

20.94 |

24.29 |

||||

|

G607/30/50I |

60 |

7 |

4 |

10 |

99.1 |

U |

4216 |

1054 |

468 |

263 |

168 |

117 |

86 |

65 |

52 |

42 |

34 |

29 |

24 |

21 |

18 |

|

G607/30/100I |

96.1 |

D |

0.11 |

0.46 |

1.03 |

1.83 |

2.86 |

4.13 |

5.65 |

7.31 |

9.4 |

11.62 |

13.85 |

16.81 |

19.29 |

22.82 |

25.97 |

||||

|

G557/30/501 |

55 |

7 |

4 |

8.5 |

90.3 |

U |

3502 |

875 |

389 |

218 |

140 |

97 |

71 |

54 |

43 |

35 |

28 |

24 |

20 |

17 |

|

|

G557/30/100I |

87.3 |

D |

0.13 |

0.5 |

1.13 |

2 |

3.15 |

4.53 |

6.17 |

8.03 |

10.29 |

12.82 |

15.11 |

18.44 |

21.32 |

24.55 |

|||||

|

G507/30/50I |

50 |

7 |

4 |

8 |

83.2 |

U |

2912 |

728 |

323 |

182 |

116 |

80 |

59 |

45 |

35 |

29 |

24 |

20 |

17 |

||

|

G507/30/100I |

80.2 |

D |

0.14 |

0.55 |

1.24 |

2.21 |

3.44 |

4.94 |

6.78 |

8.85 |

11.09 |

14.09 |

17.14 |

20.37 |

24.01 |

||||||

|

G505/30/50I |

50 |

5 |

3 |

8.5 |

62.8 |

U |

2085 |

521 |

231 |

130 |

83 |

57 |

42 |

32 |

25 |

20 |

17 |

14 |

|||

|

G505/30/100I |

59.8 |

D |

0.14 |

0.55 |

1.23 |

2.2 |

3.44 |

4.91 |

6.73 |

8.79 |

11.06 |

13.57 |

16.97 |

19.95 |

|||||||

|

G445/30/50I |

44 |

5 |

3 |

8 |

56.5 |

U |

1654 |

413 |

183 |

103 |

66 |

45 |

33 |

25 |

20 |

16 |

13 |

||||

|

G445/30/100I |

53.5 |

D |

0.16 |

0.62 |

1.4 |

2.5 |

3.92 |

5.56 |

7.59 |

9.86 |

12.71 |

15.6 |

18.7 |

||||||||

|

G385/30/50I |

38 |

5 |

3 |

7 |

49.9 |

U |

1246 |

311 |

138 |

77 |

49 |

34 |

25 |

19 |

15 |

12 |

|||||

|

G385/30/100I |

46.9 |

D |

0.18 |

0.73 |

1.64 |

2.89 |

4.51 |

6.52 |

8.93 |

11.64 |

14.82 |

18.22 |

|||||||||

|

G325/30/50I |

32 |

5 |

3 |

6 |

43.3 |

U |

884 |

221 |

98 |

55 |

35 |

24 |

18 |

13 |

10 |

||||||

|

G325/30/100I |

40.3 |

D |

0.21 |

0.86 |

1.94 |

3.44 |

5.37 |

7.68 |

10.74 |

13.35 |

16.6 |

||||||||||

|

G255/30/50I |

25 |

5 |

3 |

4.5 |

35.1 |

U |

544 |

136 |

60 |

34 |

21 |

15 |

11 |

||||||||

|

G255/30/100I |

32.1 |

D |

0.28 |

1.1 |

2.47 |

4.45 |

6.75 |

10.06 |

13.77 |

||||||||||||

1. The even load walkway plate for a single person should be over 3.0KN/m2.

2. The even load walkway plate for a double-direction should be over 5.0KN/m2.

3. The even load walkway plate for many people should be over 7.5KN/m2.

Steel Grating I Style Bearing Bars At 40mm Pitch

|

Type |

Beam |

Flange |

Abdominal |

Flange |

Theory |

Load |

ClearSpan |

||||||||||||||

|

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

|||||||

|

G6757/40/50 I |

75 |

7 |

4 |

12 |

101 |

U |

4845 |

1211 |

538 |

302 |

193 |

134 |

98 |

75 |

75 |

59 |

48 |

40 |

33 |

28 |

24 |

|

G757/40/100 I |

95.6 |

D |

0.09 |

0.37 |

0.83 |

1.47 |

2.29 |

3.31 |

4.49 |

5.89 |

5.89 |

7.44 |

9.27 |

11.35 |

13.33 |

15.66. |

18.16 |

||||

|

G657/40/50 I |

65 |

7 |

4 |

10 |

88.5 |

U |

3646 |

911 |

405 |

227 |

145 |

101 |

74 |

56 |

56 |

45 |

36 |

30 |

25 |

21 |

18 |

|

G657/40/100 I |

83.2 |

D |

0.11 |

0.42 |

0.95 |

1.69 |

2.64 |

3.83 |

5.21 |

6.75 |

6.75 |

8.72 |

10.68 |

13.1 |

15.54 |

18.1 |

21 |

||||

|

G607/40/50 I |

60 |

7 |

4 |

10 |

78.9 |

U |

3162 |

790 |

351 |

197 |

126 |

87 |

64 |

49 |

49 |

39 |

31 |

26 |

21 |

18 |

16 |

|

G607740/100 I |

75.9 |

D |

0.11 |

0.46 |

1.03 |

1.83 |

2.86 |

4.1 |

5.61 |

7.35 |

7.35 |

9.41 |

11.46 |

14.13 |

16.28 |

19.33 |

23.23 |

||||

|

G557/40/50 I |

55 |

7 |

4 |

8.5 |

71.9 |

U |

2626 |

656 |

291 |

164 |

105 |

72 |

53 |

41 |

41 |

32 |

26 |

21 |

18 |

15 |

|

|

G557/40/100 I |

68.9 |

D |

0.13 |

0.5 |

1.13 |

2.01 |

3.15 |

4.49 |

6.14 |

8.14 |

8.14 |

10.22 |

12.72 |

15.14 |

18.48 |

21.37 |

|||||

|

G507/40/50 I |

50 |

7 |

4 |

8 |

66.9 |

U |

2184 |

546 |

242 |

136 |

87 |

60 |

44 |

34 |

34 |

26 |

21 |

18 |

15 |

||

|

G507/40/100 I |

63.9 |

D |

0.14 |

0.55 |

1.24 |

2.2 |

3.45 |

4.95 |

6.74 |

8.93 |

8.93 |

11 |

13.62 |

17.18 |

20.42 |

||||||

|

G505/40/50 I |

50 |

5 |

3 |

8.5 |

50.4 |

U |

1564 |

391 |

173 |

97 |

62 |

43 |

31 |

24 |

24 |

19 |

15 |

12 |

|||

|

G50540/100 I |

47.4 |

D |

0.14 |

0.55 |

1.23 |

2.19 |

3.43 |

4.95 |

6.64 |

8.8 |

8.8 |

11.22 |

13.6 |

16.05 |

|||||||

|

G445/40/50I |

44 |

5 |

3 |

8 |

45.5 |

U |

1241 |

310 |

137 |

77 |

49 |

34 |

25 |

19 |

19 |

15 |

12 |

||||

|

G445/40/100I |

42.5 |

D |

0.16 |

0.62 |

1.4 |

2.49 |

3.88 |

5.61 |

7.68 |

10.01 |

10.01 |

12.73 |

15.64 |

||||||||

|

G385/40/50I |

38 |

5 |

3 |

7 |

40.3 |

U |

935 |

233 |

103 |

58 |

37 |

25 |

19 |

14 |

14 |

11 |

|||||

|

G38540/1001 |

37.3 |

D |

0.18 |

0.73 |

1.63 |

2.91 |

4.55 |

64 |

9.06 |

11.47 |

11.47 |

14.54 |

|||||||||

|

G325/40/50I |

32 |

5 |

3 |

6 |

35.1 |

U |

663 |

165 |

73 |

41 |

26 |

18 |

13 |

10 |

10 |

||||||

|

G325/40/100I |

32.1 |

D |

0.21 |

0.86 |

1.92 |

3.43 |

5.33 |

7.69 |

10.37 |

13.71 |

13.71 |

||||||||||

|

G255/40/50I |

25 |

5 |

3 |

4.5 |

28.7 |

U |

408 |

102 |

45 |

25 |

16 |

11 |

8 |

||||||||

|

G255/40/100 I |

25.8 |

D |

0.28 |

1.1 |

2.47 |

4.36 |

6.86 |

9.86 |

13.41 |

||||||||||||

Notes:

1. U: safe and uniformly distributed load, KN/m2.

2. D: the maximum deflection corresponding to the listed safe load.

3. Theoretical weight is the weight of 1m length of hot dipped galvanized grating.

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for OEM manufacturer Open Floor Grating - I Shape Plain And Serrated Steel Grating – Chengsen , The product will supply to all over the world, such as: Ecuador, Portugal, Korea, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The supplier abide the theory of quality the basic, trust the first and management the advanced so that they can ensure a reliable product quality and stable customers.