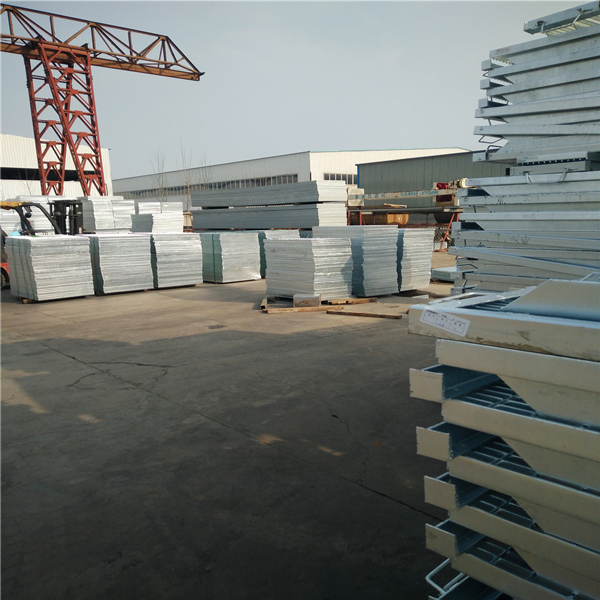

Galvanized Steel Grating Welded Steel Bar 40×3 295×690 Metal Grid Plate for Platform Walkway

Product Description

1. SYI Serrated Galvanized Steel Grating Weight specifications.

2. Serrated Galvanized Steel Grating Weight

Material of steel driveway grates grating is usually low carbon steel ,stainless steel. the size is commonly standard or as required.

Packing:Naked or as the customers' request.

certificate is ISO 9001:2000.

3. Processes:

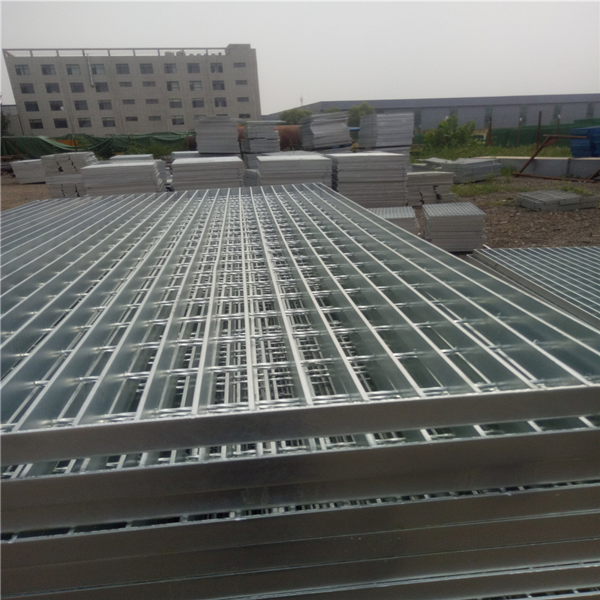

Steel grating is made by bearing bar and cross bar according to the flat-steel weft arrangement, in high-pressure spacing on resistance welder welded by cutting, incision, opening, overlock process such as processing and into customer requirements finished products.

4. Material:

Carbon steel, Stainless steel ,and so on .

5. Surface treatment:

Hot-dipped-galvanized ,electro galvanized or PVC coated

6. Size:

Standard size or OEM(Making as the customers' request).

7. Features

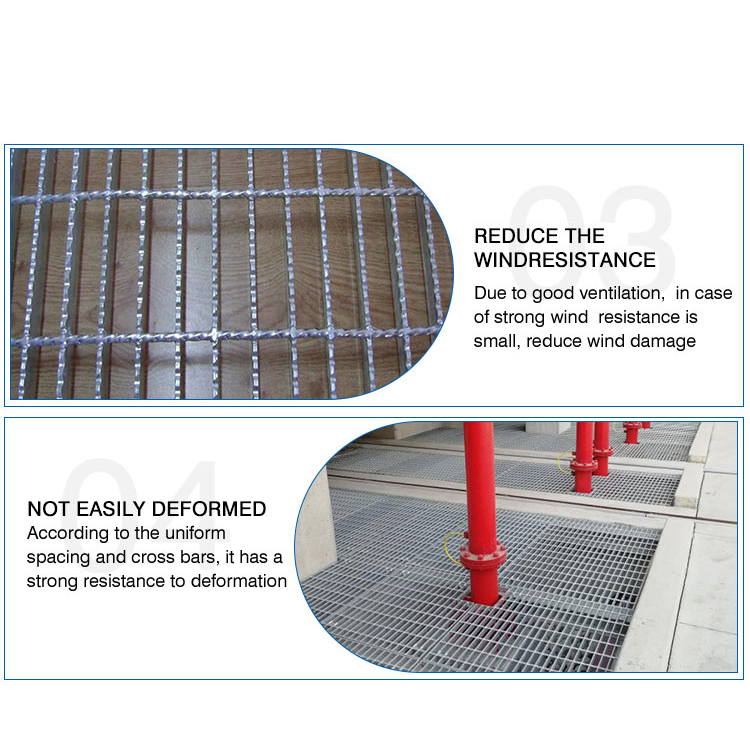

Intensity, light structure: strong grid bonding structure makes it with high load, the structure characteristics, facilitate hoisting light; Beautiful appearance, durable: hot-dip galvanized surface treatment make it fairly good corrosion resistance, the surface luster beautiful; Ventilation, lighting, heat dissipation, explosion-proof, prevent slippery properties is good; Deposition prevention dirt.

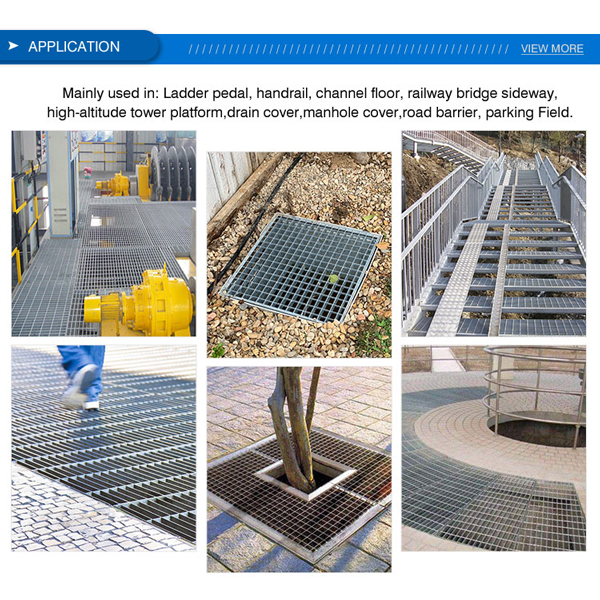

8. Useage:

Widely used in petroleum chemical industry, power plant, water and sewage treatment plants, municipal engineering, environmental sanitation engineering fields of the platform, footpath, zhanqiao pier, ditch lid, manhole cover, ladders, fences, guardrail etc.

9. Packing:

Naked or packing as the customers' request

10. Standard steel grating supplied is manufactured with a resistance-weld process using heat and pressure. Crossbars are fused to bearing bars to assure maximum strength.

| Bearing Bar | 25x2,25x3,25x4,25x4.5,25x5,30x3,30x4,30x4.5,30x5,32x5,40x5,50x5 mm etc |

| Usual Pitch | 41mm x100mm & 30mm x100mm |

| Special Pitch | 41mmx50mm, 30mmx 50mm, 33mmx 100mm, 33mmx50mm,33mmx38mm, 34mm x 100mm, 34mmx50mm,34mm x 38mm |

| Material Standard | Q235,ASTMA36,A1011,A569,S275JR,SS304&316 etc |

| Surface Treatment | galvanized,black,painted,spray coating,self color |

| Bearing Bar Type | serrated/teeth plain/smooth I bar Serrated I bar |

| HS code | 7308900000 |

| Sample | small pc for free |

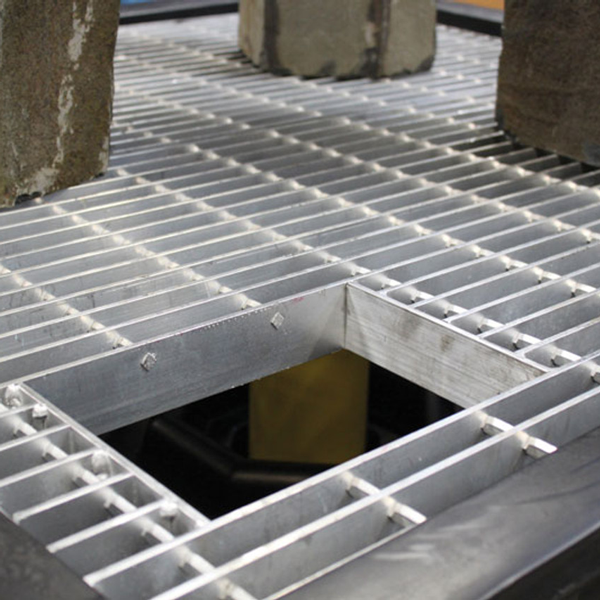

Platform grating, composed of several pieces of welded steel grating or press locked gratings are commonly installed in ships and industrial applications, such as refineries, power plants and offshore platforms.

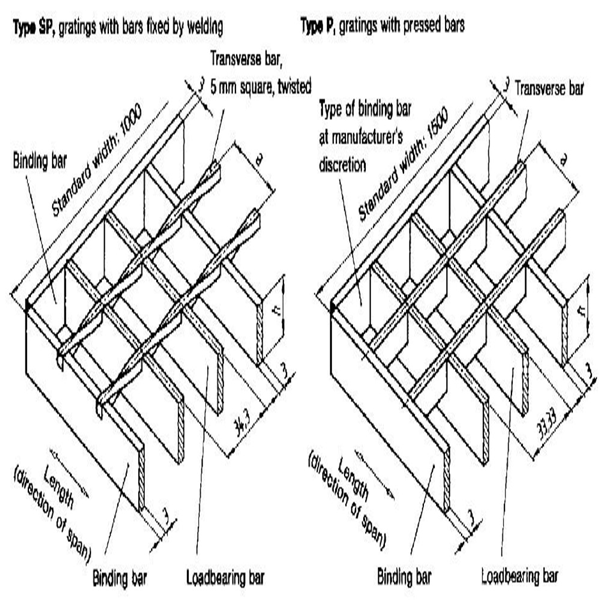

Welded or press locked gratings.

Carbon steel, galvanized steel or stainless steel material options.

Walkways and stair treads can be supplied.

Ideal for industrial applications.

Wide range of configurations for choice.

Special discount for large orders.

Project reference can be supplied for your bid.

ISO Certificated factory.

CAD or 3D drawing can be supplied for your design and construction.

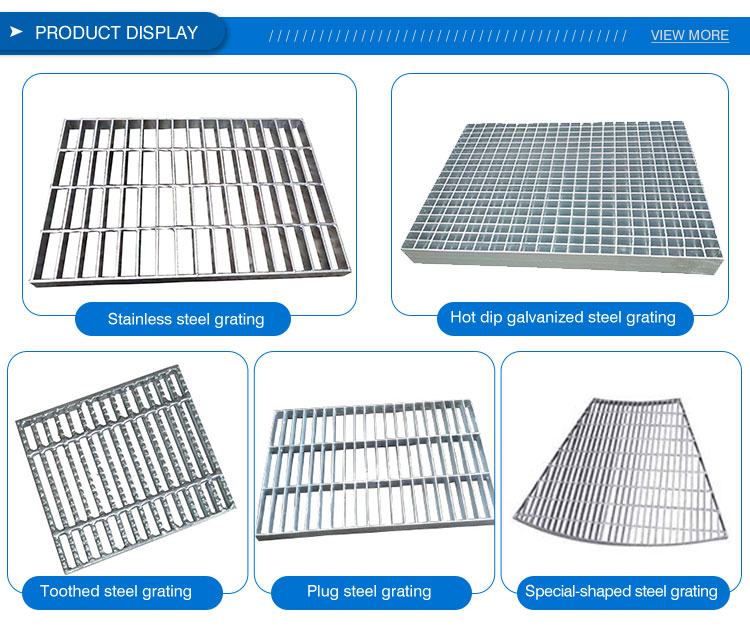

Grating Types

Welded Steel Grating

Press lock Steel Grating

Surface Types

Plain Grating

Serrated Grating

Custom Designs

Cutout

Toe plate

Stair Treads

Resources

Bearing bar spacing tables

Bearing bar spacing tables (HD)

Loading tables

Loading tables (HD)

Ordering information

Product Brochure

Advantages

High bearing capacity combined with a low specific quantity of steel.

Large and open operating places.

Easy to install.

Easy fabrications.

Toe plates and cutout service can be supplied.

Irregular shapes of gratings can be customized.

Applications

Offshore grating

Water treatment platform grating

Power plant

Parking lot

Offshore flooring grating

Water treatment platform grating

Power plant platform grating

Parking lot platform grating.

Steel grating operating platform.

Steel grating inspection platform.

Platform grating in warehouse.

Detailed Product Description

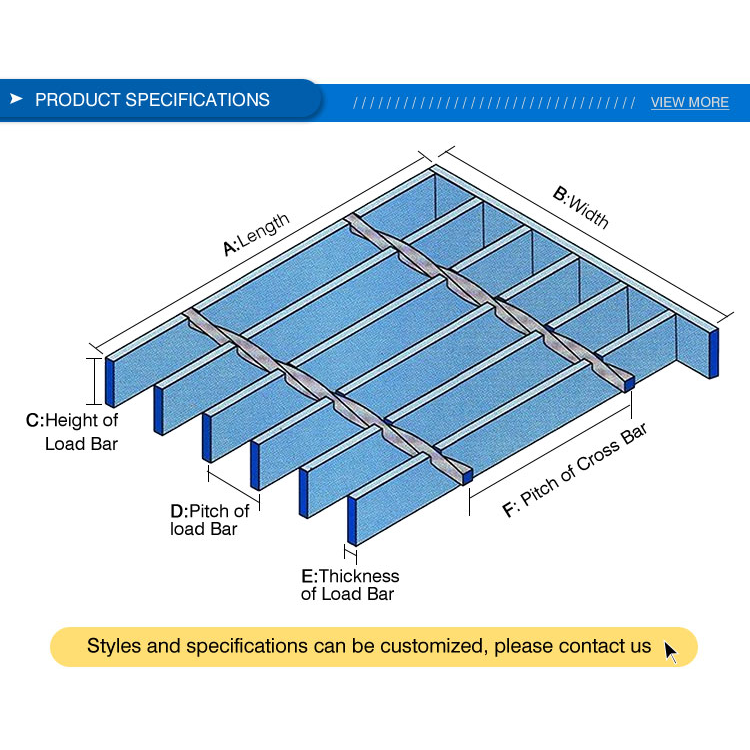

|

Bearing Bar Pitch: |

20,25,30,35,40,50mm |

Cross Bar Pitch: |

38,50,80,100mm |

|

Application: |

Platform |

Feature: |

Corrosion Protection |

|

MOQ: |

1PCS |

Certification: |

ISO9001 |

|

Panel Size: |

3x20ft,3x24ft,3x30ft,5800x1000,6096x1000,7315x1000, As Request |

Color: |

Sliver/Black |

|

High Light: |

steel grating platform, metal bar grating | ||

Width 1m Plainform Steel Grating Low Carbon Steel Length 5.8m Galvanized

Material: carbon steel

Surface treatment: hot-dipped galvanized or black

Appearance of surface: plain or serrated

Uses: welded steel grating is widely used in the platform,corriedor,bridge,well covers,stairs,fencing for petroleum,chemical, power plant,waste treatment plant,civil engineering projects and environmental projects.

Galvanized steel grating Applications:

* Anti slip bridge decking

* Bridge walkway

* Drainage systems

* Fire truck platforms

* Mass transit platforms

* Marine and ship decks

* Mezzanines

* Non-slip walkways

* Non-skid pit covers

* Slip resistant platforms

* General Industries

* Truck platforms

* Vault covers

* Wet Decks

* Wastewater treatment plant grating

* Stair treads

Tolerance of Galvanized steel grating :

The allowed deviation of length is +0/-5mm, while the allowed deviation of width is +/-5 mm. The non-perpendicularity of bearing bar is allowed no more than 10% of width of bearing bar. Cross bar surface should not surpass bearing bar surface 1mm, beginning & end of cross bar should not surpass the end surfaces of two sides of grating 2mm.

Our Service

1. Any inquiries will be replied within 24 hours.

2. Professional factory for 20 years with advanced facility.

3. Quality guarantee

A. All products will have been strictly inspected by our inspector before packing.

B. Welcome you to our factory to supervise the production processing and inspect

the goods quality at any time.

C. After receipt of the goods within 15 days, have any quality problem,you could raise an objection.

4. Fast delivery

A.Sample order in stock, will be delivery within 3 to 7 days.

B.The goods will delivery on time according to the contract.

5. Payment

T/T, L/C, Western Union, Escrow.

6. Shipping

By sea, we also have strong cooperation with DHL, TNT, UPS, FEDEX, EMS.

7. Best Service after-sales

At any time,all free service

| No. | Item | Description |

| 1 | Bearing Bar | 25x3, 25x4, 25x4.5, 25x5, 30x3, 30x4, 30x4.5, 30x5, 32x5, 40x5,

50x5, 65x5, 75x6, 75x10,100x10mm etc; I bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc US standard: 1'x3/16', 1 1/4'x3/16', 1 1/2'x3/16', 1'x1/4', 1 1/4'x1/4', 1 1/2'x1/4', 1'x1/8', 1 1/4'x1/8', 1 1/2'x1/8' etc. |

| 2 | Bearing Bar Pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3, 32.5, 34.3, 35, 38.1,

40, 41.25, 60, 80mm etc US standard: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc. |

| 3 | Twisted Cross Bar Pitch | 38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2' & 4' etc |

| 4 | Material Grade | ASTM A36, A1011, A569, Q235, S275JR, SS304,

Mild steel & Low carbon steel, etc |

| 5 | Surface Treatment | Black, self colour, hot dip galvanized, painted, spray coating |

| 6 | Grating Style | Plain / Smooth, Serrated /teeth, I bar, serrated I bar |

|

7

|

Standard | China: YB/T 4001.1-2007,

USA: ANSI/NAAMM(MBG531-88), UK: BS4592-1987, Australia: AS1657-1985, Japan:JIS |

| 8 | Application | -Rotation ways, channels, and platforms for pump rooms and engine rooms in various ships;

-Flooring in various bridges such as railway bridge sidewalks, over-bridges across the street; -Platforms for oil extraction sites, car washing sites and air towers; -Fencings for car-parks, buildings and roads; drainage trench covers and drainage pit covers for high strength . |

Platform grating in plant.

The Classification Of Platform Steel Grille

1. According to the welding method, it can be divided into: pressure welding type platform steel grid plate, embedded type platform steel grid plate, lock type platform steel grid plate and through welding type platform steel grid plate.

2. According to the shape of the side surface of the load flat steel, it can be divided into: plane steel plate, tooth steel plate and "work" type steel plate, etc.

3. According to its use, it can be divided into: general purpose steel plate and special purpose steel plate, such as: gutter cover plate, step plate and so on.

4. According to the load flat steel distance: two adjacent center distance of load flat steel, commonly used 30MM, 40MM and 60MM three.

5. According to the bar spacing: the center spacing of two adjacent bar is usually 50MM, 100MM, two kinds.

The Characteristics Of The Platform Steel Grid

1. Can be welded around the kick plate (baffle plate), pattern plate guard plate, installation of connectors and other accessories.

2. Use flat steel with different specifications from the flat steel, or use Angle steel, channel steel, square pipe, etc.

3. Handle and hinge can be installed on the steel plate of the platform that needs to be moved or opened frequently.

4. The welding standard for the edge of the platform steel grille is: one weld for every five parts of series 1; Series 2 every four welding one; Series 3 one weld every three. The weld is not less than 3mm single side fillet welding, the weld length is 20mm.

Platform Steel Grating Specifications

1. The steel plate with 30mm flat steel spacing is the most widely used variety in the industrial field. In the commonly used steel grille series, it has the strongest resistance to surface impact.

2. The steel plate with 40mm flat steel spacing is the most economical and portable variety. In the minimum span of the occasion, is the most ideal choice.

3. Steel plate with flat steel spacing of 60mm and crossbar spacing of 50mm is developed specially for the application of mining industry. It solves the problem of mineral sputtering on the plate surface, which is often designated for the processing plant, transfer station and the plate surface of crushing system in mining industry.

Platform Steel Grating Material

1. Flat steel and bar are made of GB/T700 Q235, according to user requirements, can also be made of other materials.

2. Flat steel adopts hot rolled flat steel or longitudinal shear hot rolled or cold rolled steel strip.

3. The allowable deviation of flat steel size shall comply with the provisions of Table I YB/T4001.1-2007.

4. Toothed flat steel adopts hot rolled flat steel or hot rolled or cold rolled steel strip after longitudinal shear and punching teeth. The tooth size shall not be less than 5 teeth per 100mm.

5. I-shaped flat steel section size and section moment of inertia.

Platform Steel Grating Application

Widely used in chemical, electric power, tap water, sewage treatment, port terminals, building modification, shipbuilding, self-walking parking lot, municipal engineering, sanitation engineering and other fields of platform, walkway, trestle, trench cover, manhole cover, ladder, fence, etc. Beautiful style, easy to install, is a new type of building products.