Manufacturer of Pressure Locked Steel Grating - I Shape Plain And Serrated Steel Grating – Chengsen

Manufacturer of Pressure Locked Steel Grating - I Shape Plain And Serrated Steel Grating – Chengsen Detail:

I Type Steel Plate Surface Treatment

Hot galvanizing, cold galvanizing, painting, dipping rust oil, no treatment (general stainless steel without treatment).

I Type Steel Plate Production Method

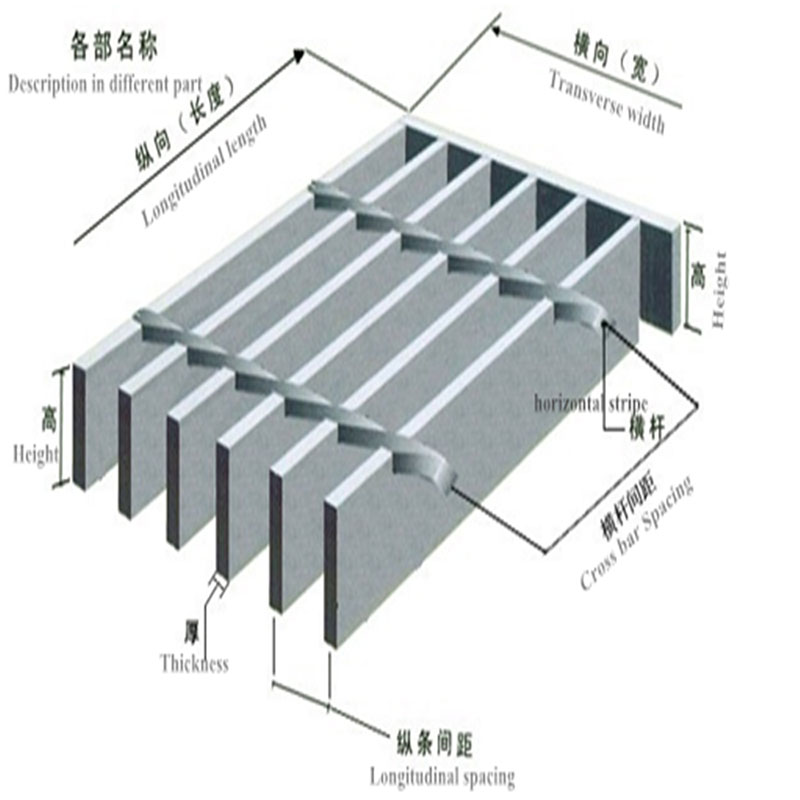

I type steel plate is composed of load flat steel and horizontal bar arranged according to a certain spacing of longitude and latitude, using 200 tons of hydraulic resistance welding automation equipment welding into the original plate, after cutting, opening, rimming and other processes processed into customer requirements.

Steel Grating I Type, Bearing Bars At 30mm Pitch

|

Type |

Beam |

Flange |

Abdominal |

Flange |

Theory |

Load |

ClearSpan |

||||||||||||||

|

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

|||||||

|

G757/30/50I |

75 |

7 |

4 |

12 |

126.1 |

U |

6460 |

1615 |

717 |

403 |

258 |

179 |

131 |

100 |

79 |

64 |

53 |

44 |

38 |

32 |

28 |

|

G757/30/100 I |

120.7 |

D |

0.09 |

0.37 |

0.83 |

1.47 |

2.3 |

3.31 |

4.5 |

5.88 |

7.47 |

9.25 |

11.26 |

13.3 |

15.89 |

18.11 |

20.99 |

||||

|

G657/30/50I |

65 |

7 |

4 |

10 |

110.1 |

U |

4862 |

1215 |

540 |

303 |

194 |

135 |

99 |

75 |

60 |

48 |

40 |

33 |

28 |

24 |

21 |

|

G657/30/100I |

104.8 |

D |

0.11 |

0.42 |

0.95 |

1.69 |

2.65 |

3.83 |

5.22 |

6.77 |

8.71 |

10.67 |

13.07 |

15.36 |

18.05 |

20.94 |

24.29 |

||||

|

G607/30/50I |

60 |

7 |

4 |

10 |

99.1 |

U |

4216 |

1054 |

468 |

263 |

168 |

117 |

86 |

65 |

52 |

42 |

34 |

29 |

24 |

21 |

18 |

|

G607/30/100I |

96.1 |

D |

0.11 |

0.46 |

1.03 |

1.83 |

2.86 |

4.13 |

5.65 |

7.31 |

9.4 |

11.62 |

13.85 |

16.81 |

19.29 |

22.82 |

25.97 |

||||

|

G557/30/501 |

55 |

7 |

4 |

8.5 |

90.3 |

U |

3502 |

875 |

389 |

218 |

140 |

97 |

71 |

54 |

43 |

35 |

28 |

24 |

20 |

17 |

|

|

G557/30/100I |

87.3 |

D |

0.13 |

0.5 |

1.13 |

2 |

3.15 |

4.53 |

6.17 |

8.03 |

10.29 |

12.82 |

15.11 |

18.44 |

21.32 |

24.55 |

|||||

|

G507/30/50I |

50 |

7 |

4 |

8 |

83.2 |

U |

2912 |

728 |

323 |

182 |

116 |

80 |

59 |

45 |

35 |

29 |

24 |

20 |

17 |

||

|

G507/30/100I |

80.2 |

D |

0.14 |

0.55 |

1.24 |

2.21 |

3.44 |

4.94 |

6.78 |

8.85 |

11.09 |

14.09 |

17.14 |

20.37 |

24.01 |

||||||

|

G505/30/50I |

50 |

5 |

3 |

8.5 |

62.8 |

U |

2085 |

521 |

231 |

130 |

83 |

57 |

42 |

32 |

25 |

20 |

17 |

14 |

|||

|

G505/30/100I |

59.8 |

D |

0.14 |

0.55 |

1.23 |

2.2 |

3.44 |

4.91 |

6.73 |

8.79 |

11.06 |

13.57 |

16.97 |

19.95 |

|||||||

|

G445/30/50I |

44 |

5 |

3 |

8 |

56.5 |

U |

1654 |

413 |

183 |

103 |

66 |

45 |

33 |

25 |

20 |

16 |

13 |

||||

|

G445/30/100I |

53.5 |

D |

0.16 |

0.62 |

1.4 |

2.5 |

3.92 |

5.56 |

7.59 |

9.86 |

12.71 |

15.6 |

18.7 |

||||||||

|

G385/30/50I |

38 |

5 |

3 |

7 |

49.9 |

U |

1246 |

311 |

138 |

77 |

49 |

34 |

25 |

19 |

15 |

12 |

|||||

|

G385/30/100I |

46.9 |

D |

0.18 |

0.73 |

1.64 |

2.89 |

4.51 |

6.52 |

8.93 |

11.64 |

14.82 |

18.22 |

|||||||||

|

G325/30/50I |

32 |

5 |

3 |

6 |

43.3 |

U |

884 |

221 |

98 |

55 |

35 |

24 |

18 |

13 |

10 |

||||||

|

G325/30/100I |

40.3 |

D |

0.21 |

0.86 |

1.94 |

3.44 |

5.37 |

7.68 |

10.74 |

13.35 |

16.6 |

||||||||||

|

G255/30/50I |

25 |

5 |

3 |

4.5 |

35.1 |

U |

544 |

136 |

60 |

34 |

21 |

15 |

11 |

||||||||

|

G255/30/100I |

32.1 |

D |

0.28 |

1.1 |

2.47 |

4.45 |

6.75 |

10.06 |

13.77 |

||||||||||||

1. The even load walkway plate for a single person should be over 3.0KN/m2.

2. The even load walkway plate for a double-direction should be over 5.0KN/m2.

3. The even load walkway plate for many people should be over 7.5KN/m2.

Steel Grating I Style Bearing Bars At 40mm Pitch

|

Type |

Beam |

Flange |

Abdominal |

Flange |

Theory |

Load |

ClearSpan |

||||||||||||||

|

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

|||||||

|

G6757/40/50 I |

75 |

7 |

4 |

12 |

101 |

U |

4845 |

1211 |

538 |

302 |

193 |

134 |

98 |

75 |

75 |

59 |

48 |

40 |

33 |

28 |

24 |

|

G757/40/100 I |

95.6 |

D |

0.09 |

0.37 |

0.83 |

1.47 |

2.29 |

3.31 |

4.49 |

5.89 |

5.89 |

7.44 |

9.27 |

11.35 |

13.33 |

15.66. |

18.16 |

||||

|

G657/40/50 I |

65 |

7 |

4 |

10 |

88.5 |

U |

3646 |

911 |

405 |

227 |

145 |

101 |

74 |

56 |

56 |

45 |

36 |

30 |

25 |

21 |

18 |

|

G657/40/100 I |

83.2 |

D |

0.11 |

0.42 |

0.95 |

1.69 |

2.64 |

3.83 |

5.21 |

6.75 |

6.75 |

8.72 |

10.68 |

13.1 |

15.54 |

18.1 |

21 |

||||

|

G607/40/50 I |

60 |

7 |

4 |

10 |

78.9 |

U |

3162 |

790 |

351 |

197 |

126 |

87 |

64 |

49 |

49 |

39 |

31 |

26 |

21 |

18 |

16 |

|

G607740/100 I |

75.9 |

D |

0.11 |

0.46 |

1.03 |

1.83 |

2.86 |

4.1 |

5.61 |

7.35 |

7.35 |

9.41 |

11.46 |

14.13 |

16.28 |

19.33 |

23.23 |

||||

|

G557/40/50 I |

55 |

7 |

4 |

8.5 |

71.9 |

U |

2626 |

656 |

291 |

164 |

105 |

72 |

53 |

41 |

41 |

32 |

26 |

21 |

18 |

15 |

|

|

G557/40/100 I |

68.9 |

D |

0.13 |

0.5 |

1.13 |

2.01 |

3.15 |

4.49 |

6.14 |

8.14 |

8.14 |

10.22 |

12.72 |

15.14 |

18.48 |

21.37 |

|||||

|

G507/40/50 I |

50 |

7 |

4 |

8 |

66.9 |

U |

2184 |

546 |

242 |

136 |

87 |

60 |

44 |

34 |

34 |

26 |

21 |

18 |

15 |

||

|

G507/40/100 I |

63.9 |

D |

0.14 |

0.55 |

1.24 |

2.2 |

3.45 |

4.95 |

6.74 |

8.93 |

8.93 |

11 |

13.62 |

17.18 |

20.42 |

||||||

|

G505/40/50 I |

50 |

5 |

3 |

8.5 |

50.4 |

U |

1564 |

391 |

173 |

97 |

62 |

43 |

31 |

24 |

24 |

19 |

15 |

12 |

|||

|

G50540/100 I |

47.4 |

D |

0.14 |

0.55 |

1.23 |

2.19 |

3.43 |

4.95 |

6.64 |

8.8 |

8.8 |

11.22 |

13.6 |

16.05 |

|||||||

|

G445/40/50I |

44 |

5 |

3 |

8 |

45.5 |

U |

1241 |

310 |

137 |

77 |

49 |

34 |

25 |

19 |

19 |

15 |

12 |

||||

|

G445/40/100I |

42.5 |

D |

0.16 |

0.62 |

1.4 |

2.49 |

3.88 |

5.61 |

7.68 |

10.01 |

10.01 |

12.73 |

15.64 |

||||||||

|

G385/40/50I |

38 |

5 |

3 |

7 |

40.3 |

U |

935 |

233 |

103 |

58 |

37 |

25 |

19 |

14 |

14 |

11 |

|||||

|

G38540/1001 |

37.3 |

D |

0.18 |

0.73 |

1.63 |

2.91 |

4.55 |

64 |

9.06 |

11.47 |

11.47 |

14.54 |

|||||||||

|

G325/40/50I |

32 |

5 |

3 |

6 |

35.1 |

U |

663 |

165 |

73 |

41 |

26 |

18 |

13 |

10 |

10 |

||||||

|

G325/40/100I |

32.1 |

D |

0.21 |

0.86 |

1.92 |

3.43 |

5.33 |

7.69 |

10.37 |

13.71 |

13.71 |

||||||||||

|

G255/40/50I |

25 |

5 |

3 |

4.5 |

28.7 |

U |

408 |

102 |

45 |

25 |

16 |

11 |

8 |

||||||||

|

G255/40/100 I |

25.8 |

D |

0.28 |

1.1 |

2.47 |

4.36 |

6.86 |

9.86 |

13.41 |

||||||||||||

Notes:

1. U: safe and uniformly distributed load, KN/m2.

2. D: the maximum deflection corresponding to the listed safe load.

3. Theoretical weight is the weight of 1m length of hot dipped galvanized grating.

Product detail pictures:

Related Product Guide:

We pursue the management tenet of Quality is superior, Service is supreme, Reputation is first, and will sincerely create and share success with all clients for Manufacturer of Pressure Locked Steel Grating - I Shape Plain And Serrated Steel Grating – Chengsen , The product will supply to all over the world, such as: Uganda, Barcelona, Jordan, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers' satisfaction and achieve win-win situation .

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!