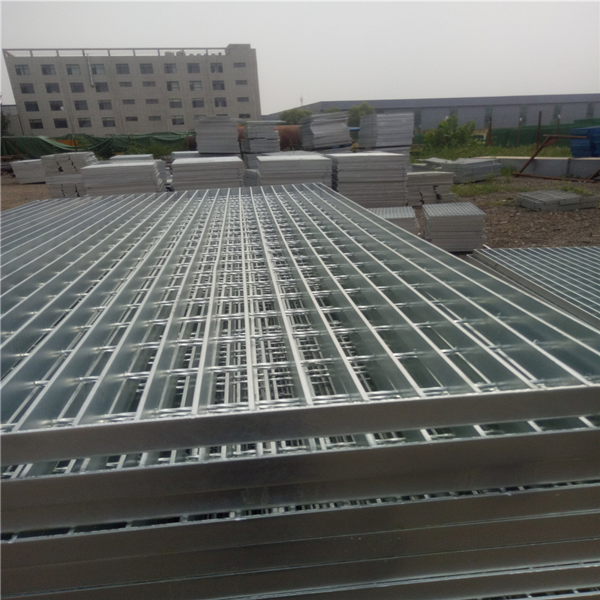

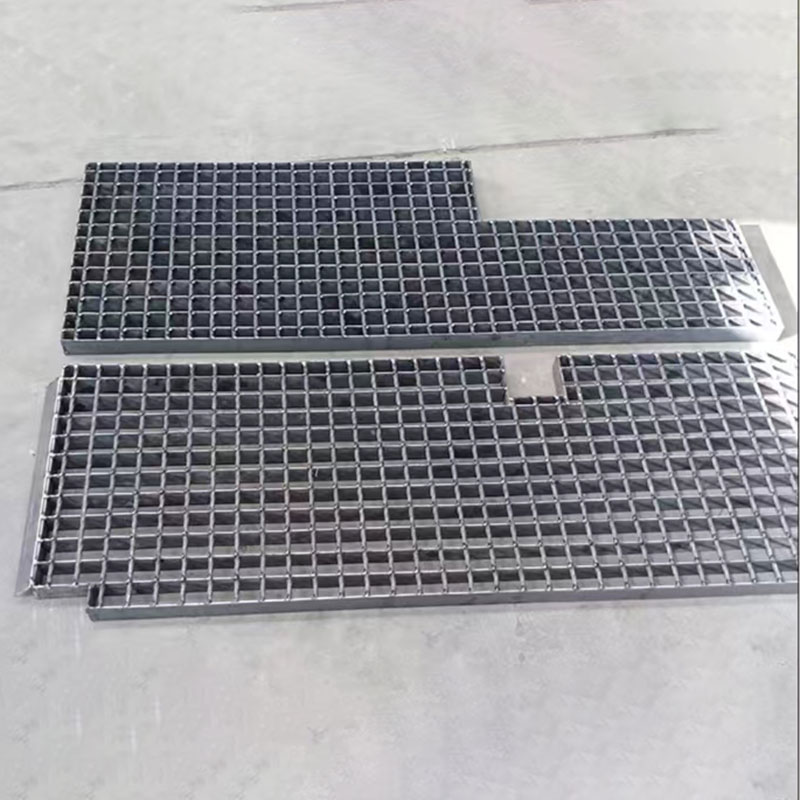

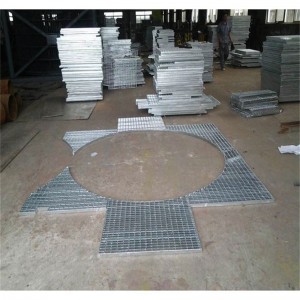

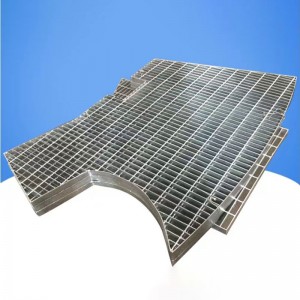

Customized Fabricated Industrial Platform Irregular Special Shaped Steel Grating

Description

Stainless steel grating material is stainless steel plate, the production process is much the same as the ordinary steel plate, but it does not use spray painting or hot dip galvanized anti-corrosion treatment, but need to use surface polishing treatment to get rid of welding slag or scar left in the welding process.

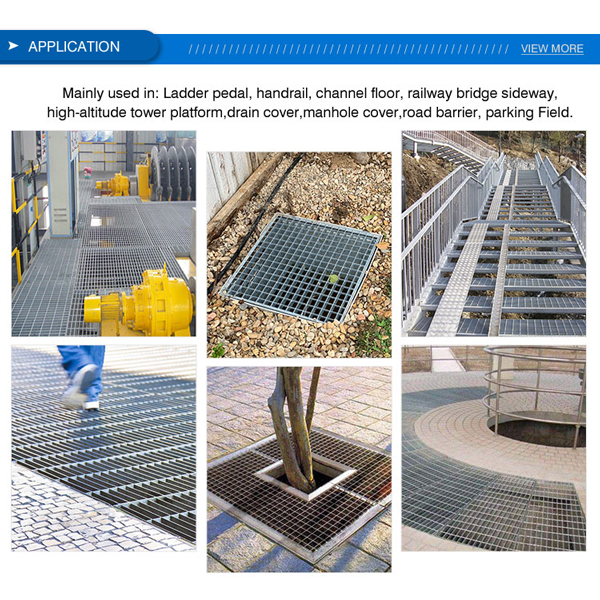

Stainless steel grating is widely used in various factories and engineering projects at home and abroad.

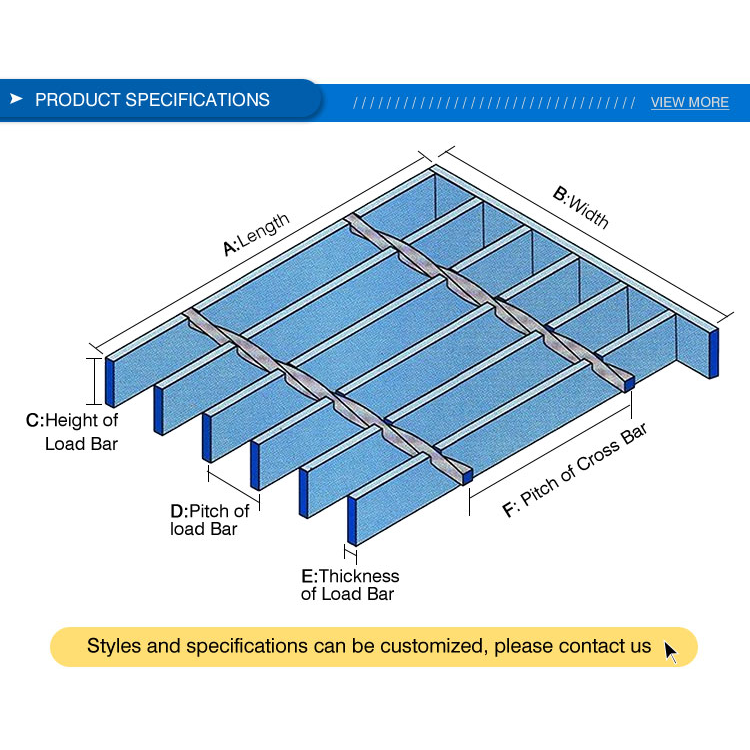

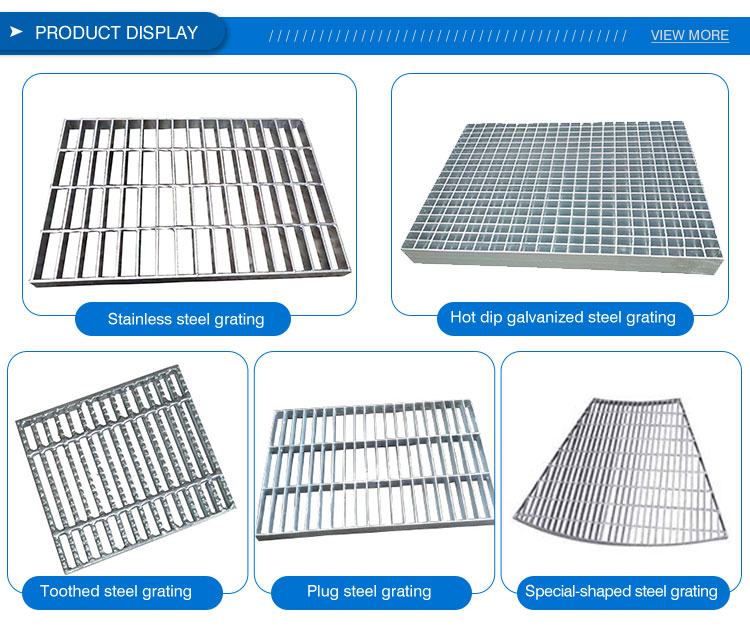

Classification: Plane type, tooth type and I type, there are more than 200 specifications of varieties (according to different use environment, the surface can be different protection treatment).

Material: 304, 201, 316, 316L, 310, 310S and other materials can be made of steel plate

Stainless steel grating specifications: 304, 316L, 321, 201, (301 coil belt) domestic stainless steel material: 430, 409, 201

Stainless steel plate 304 plate thickness 0.12mm-65mm

Stainless steel plate 316L# plate thickness 0.5mm-16mm

Plate surface treatment: 8K mirror,2B smooth surface, sanding (wire drawing, sand drawing), titanium, rice, oil drawing,BA board

Grating width: 1000mm*2000mm, 1219mm*2438mm, 1219*3048, 1219*3500,

1219*4000, 1500mm*3000mm, 1500mm*6000mmm,

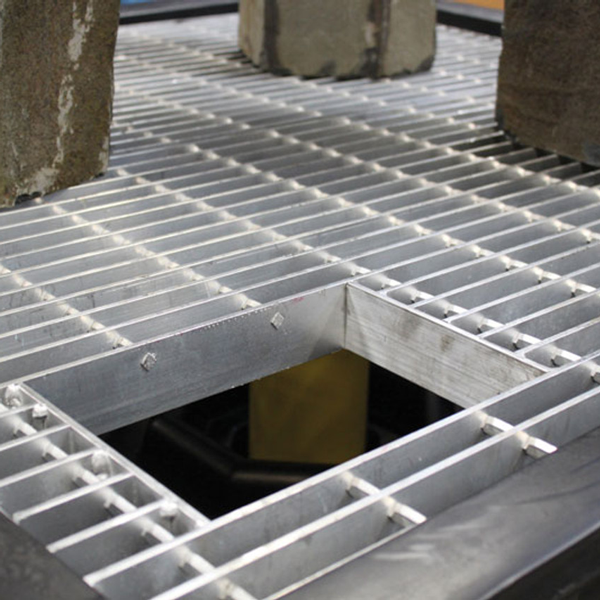

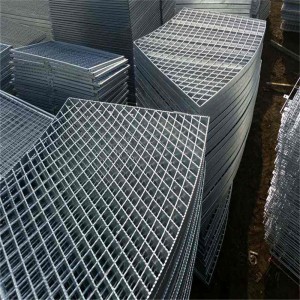

Usage: power plant, chemical plant, oil refinery, steel plant, machinery factory, shipyard, paper mill, cement factory, medicine, food processing plant and bridge engineering, municipal engineering projects, etc.

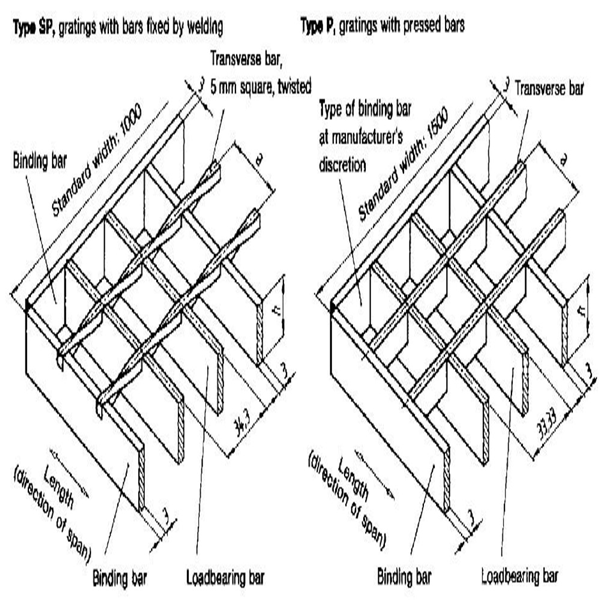

Production Method

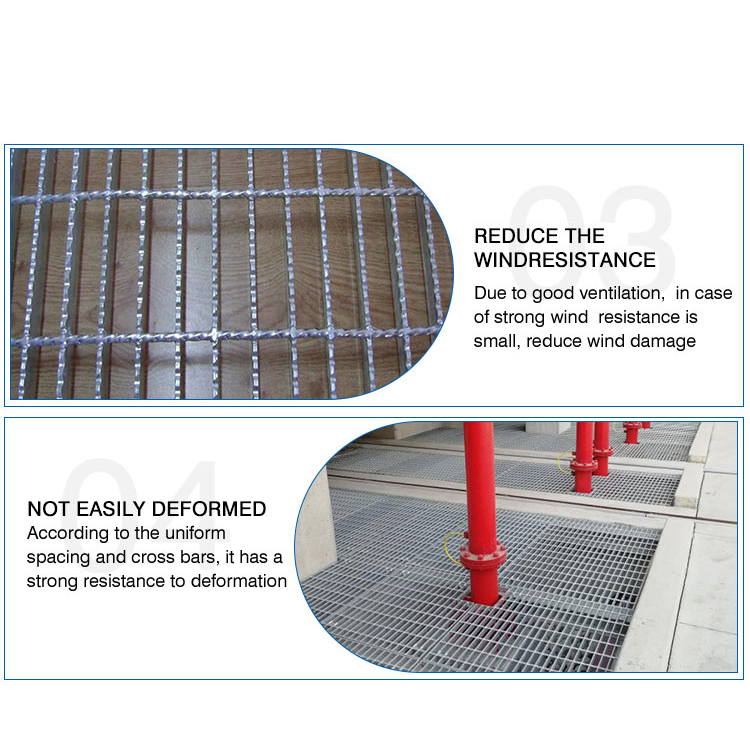

There are two kinds of machine pressure welding and manufacturing technology: machine pressure welding using high voltage resistance pressure welding machine, the manipulator will take the initiative to put the bar across the flat steel evenly placed, after strong welding power and liquid pressure will be welded into the flat steel bar, and then can get solder joint consolidation, stability and high strength of high-quality steel plate. The steel lattice plate is first punched on the flat steel, and then the bar is placed in the hole for spot welding. There will be space between the bar and the flat steel, but each contact point can be welded to the same melting connection of the flat steel and twist steel, so the welding will be stronger, the strength will be improved, but the appearance is not as beautiful as the pressure welding! Advantages of stainless steel lattice plate: light weight, high strength, bearing capacity, economical material, ventilation and light, modern style, beautiful appearance, anti-slip safety, easy to clean, simple device, durable.

Stainless steel plate is the material is stainless steel plate, the production process is much the same as the ordinary steel plate, but it does not use spray painting or hot dip galvanized anti-corrosion treatment, but need to use surface polishing treatment to get rid of welding slag or scar left in the welding process. Stainless steel plate is widely used in various factories and engineering projects at home and abroad. The classification of stainless steel plate: plane type, tooth type and I type, there are more than 200 specifications (according to the different use of the environment, the surface can be different protective treatment) the specific size and type also need the majority of customers to contact our company's e-commerce personnel. Can be made according to your requirements.

Advantages

1. Light weight, high strength, large bearing capacity, economical material, ventilation and light, modern style, beautiful appearance, non-slip safety, easy to clean, simple installation, durable, stainless steel plate is not easy to rust, because its composition contains chromium. After oxidation, a passivation film will be formed on the surface. When the chromium content of stainless steel exceeds 12, the iron or steel will not be exposed to oxygen. In general, a protective film is formed on the surface.

2. The use of stainless steel lattice plate is much longer than the use of galvanized hot soak. It can be used for a maximum of three to 40 years in an environment containing acids and bases.

3. The chromium content of the stainless steel plate makes it a protective film on the surface without any anti-corrosion treatment.

4. Stainless steel plate is widely used in irritating and corrosive places, such as coking plants, oil refineries, shipyards and ship oil drilling platforms.

5. The materials used for the stainless steel plate are 201.304.316.316L respectively. Different materials have different chromium content. The higher the chromium content, the higher the price. It depends on individual needs.

All in all, stainless steel lattice plate with light weight, high strength, high bearing capacity, large bearing capacity, material economy, through the wind transmission, modern style, beautiful appearance, non-sliding safety, easy cleaning, simple installation, durable.